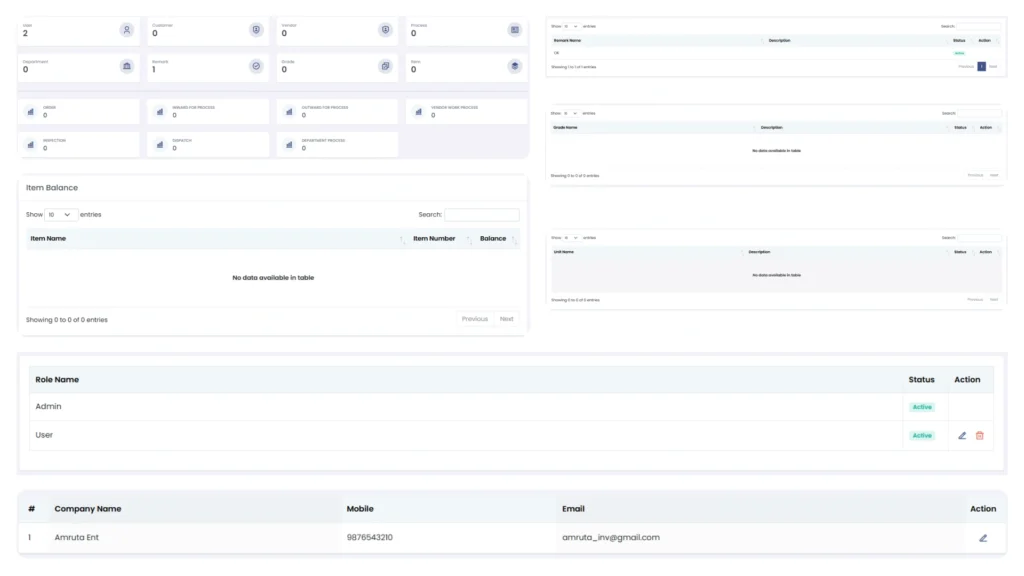

Amruta Industries is a leading manufacturing company known for its precision-engineered products and commitment to quality. With a vast network of vendors and subvendors, the company operates a complex supply chain that requires seamless coordination and efficient production management.

To enhance operational efficiency, Amruta Industries sought a robust Vendor & Production Management System. Their goal was to streamline inventory tracking, monitor production workflows, and optimize outsourced manufacturing processes. By implementing a digital solution, they aimed to reduce material loss, improve vendor coordination, and drive overall productivity.

Take the First Step Today

Schedule Your Consultation and Unlock Growth Opportunities !

Objective:

Amruta Industries aimed to enhance its vendor and production management by implementing a system that offers real-time inventory tracking, streamlined production workflows, and efficient subvendor management. The goal was to reduce material wastage, improve operational efficiency, and optimize resource utilization.

Challenges:

- Lack of Real-Time Inventory Tracking – Difficulty in monitoring vendor-supplied materials led to stock shortages and overstocking.

- Complex Production Workflow – Inefficiencies in coordinating multiple production stages across departments and subvendors caused delays.

- Material Loss & Inefficiencies – The absence of a centralized tracking system resulted in increased wastage and higher operational costs.

Solutions:

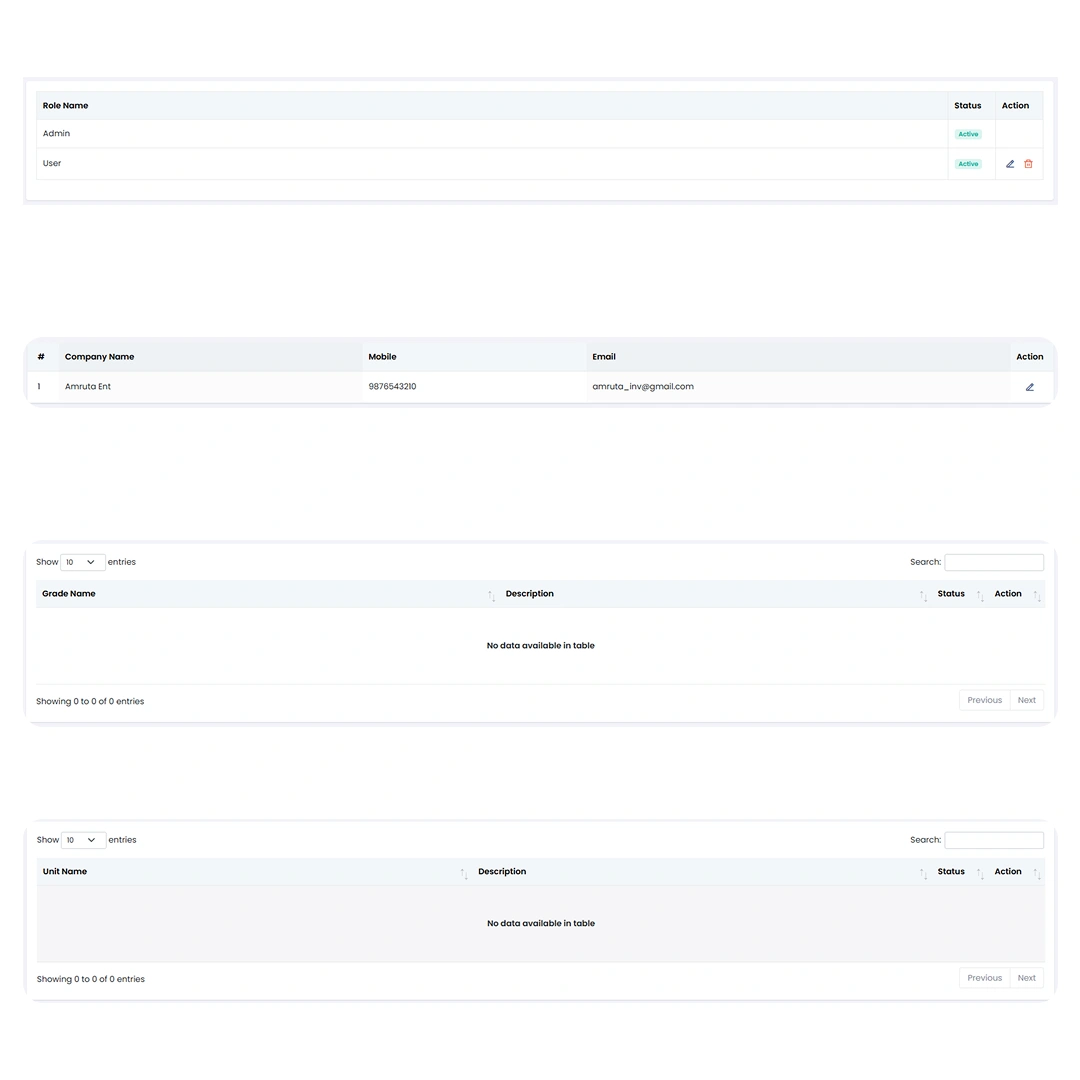

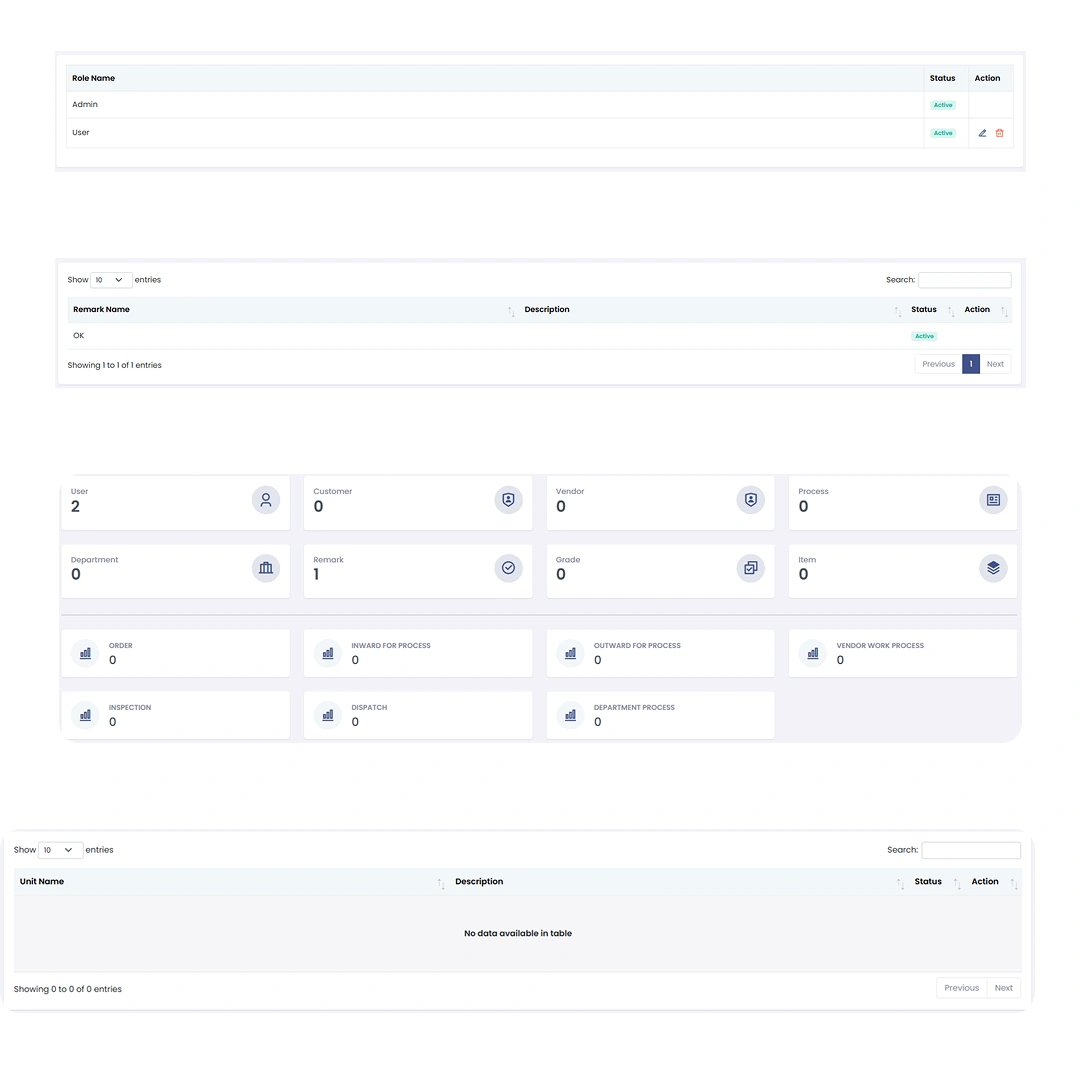

- Real-Time Inventory Management – Implemented a digital system for live tracking of vendor-supplied materials, reducing stock discrepancies.

- Automated Production Workflow – Developed an integrated system to streamline department-wise and subvendor production tracking.

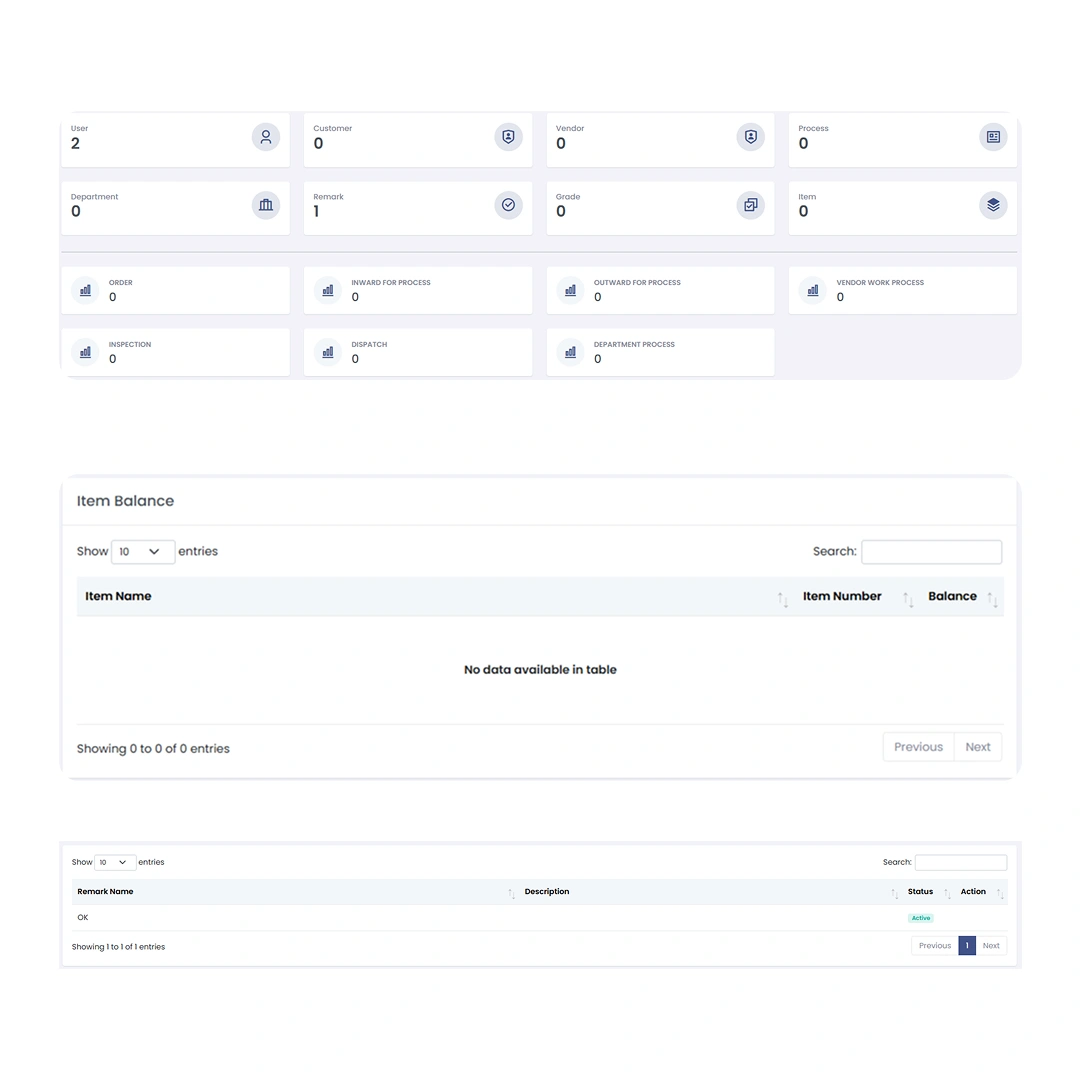

- Centralized Reporting & Monitoring – Introduced a dashboard for real-time insights, improving decision-making and operational control.

Results:

- Improved Inventory Accuracy – Real-time tracking reduced stock discrepancies and optimized inventory management.

- Enhanced Production Efficiency – Automated workflows streamlined processes, reducing delays and errors.

- Optimized Subvendor Management – Better tracking minimized outsourcing inefficiencies, improving overall output.

- Cost Savings & Productivity Boost – Reduced material wastage and better workflow management led to increased efficiency and profitability.

Conclusion:

By implementing a comprehensive Vendor & Production Management System, Amruta Industries successfully overcame its operational challenges. The digital transformation improved inventory accuracy, streamlined production processes, and optimized resource management. As a result, the company achieved higher productivity, reduced costs, and enhanced overall efficiency.

Begin Your Digital Transformation

Minimize risks and establish a strong foundation for your ambitious projects.

Subscribe

Subscribe for updates, exclusive offers, and expert insights straight to your inbox !